Screen Printing Services

Screen Printing is the backbone of our company. We have over 50 years of staff experience handling thousands of imprints regularly to ensure every print, garment, and box is ready for delivery. We offer many methods of screen printing to display your company logo or promotional products, no matter how big or small your next order may be. See below the services we offer to match your order needs and feel free to contact us for more information.

Turnaround times for every order are two weeks from when the order is placed.*

Screen Printing: Printing Methods & Common Inks

First, we have an example of plastisol ink printing. Plastisol is the most common type of ink used in screen printing. The ink is thick, PVC-based, easily modified, and cured using heat to provide durability and vibrant colors. Great for dark-colored garments

Plastisol is adaptive across a majority of garments in the screen printing industry. Whether it’s nylon or polyester, plastisol inks can manage the purging dye migration to keep colors opaque, not to mention versatile in any screen mesh, even upholding the quality of half-tones.

Next, we have an example of discharge ink printing. Discharge ink removes the dye from the fabric, creating a lighter pattern on a darker-colored fabric. This method of printing is known for its soft hand and natural look without layers of ink. Discharge inks are different than traditional plastisol.

Discharge inks replace the fabric of the garments, soaking into the fibers, rather than plastisol, which lays on top of the fabric. Pantone matching is not achieved since colors will reflect differently based on the garment dye.

Used widely across the screen printing industry is spot color printing. Spot color is the most common method of screen printing, where pre-mixed colors are laid down to translate that exact color throughout the print on the garment. Pantone matching is ideal with vector elements such as logos, text, and icons.

Spot color printing is ideal when color accuracy and consistency are crucial due to each spot color requiring its own screen, although limiting the number of colors in your design. Brands or company logos with few specific colors are perfect examples.

Last but not least, we have simulated process printing. Simulated process printing often called “spot-process” uses two six colors to create a full range of colors. It is as inexpensive as process-color printing but does not produce the same quality of color reproduction.

Simulated process printing is much like CMYK but often requires additional colors outside of cyan, magenta, yellow, and black. Great for a full-color image that includes specific PMS colors and allows printers more flexibility to reproduce images that may not be possible with Spot or CMYK.

Screen Printing: Speciality Inks

First and the most common specialty ink are glitter/metallic ink. Glitter/Metallic ink can be used to create eye-catching and visually appealing designs. You can create sparkle, shimmer, or even dimensions to your design.

These inks add some bling to your design but there can be cons to it as well. Whereas it looks great could also not feel great as metallic and glitter inks are rougher to the touch than traditional inks.

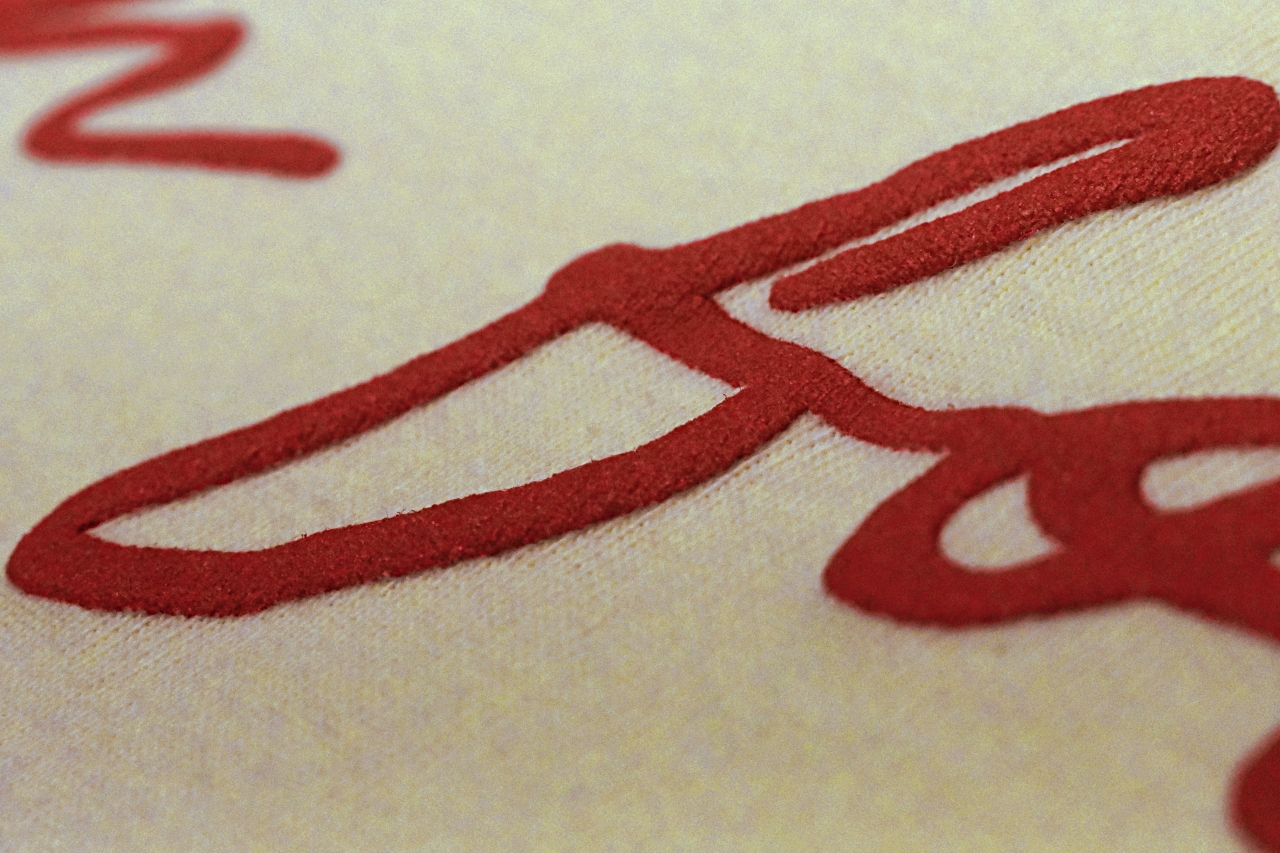

Next, we have an example of puff ink. Puff ink can create a 3D and raised effect, adding texture and interest to your designs. Puff ink is also very soft hand, making it ideal for comfort and aesthetics.

Puff prints are an ink additive that uses a heat-activating foaming agent. When the design is printed, the garment goes down the dryer for the ink to cure, during that process the ink is heated and then expands to provide a 3-dimensional look. We recommend these prints in one color for best results.

Another simple addition to your design can be Gel ink. Gel ink provides a sleek, tone-on-tone finish to give the design a soft-touch finish. Gel ink is a water-based gel that requires minimum setup to achieve a different style of print.

Gel ink can be used in many different ways. You can achieve a tone-on-tone look with gel ink, or if you want a “wet” look you can do that as well. Want to add gel on top of your image for a glossy look? Yeah, gel ink can do that too.

Lastly, we have an ink that can be seen by day and by night. Glow-in-the-dark ink can be used to create many special effects such as glow effects and blacklight effects. Does require an underbase.

Glow-in-the-dark inks are another common ink additive that allows all or some aspects of your design to change when exposed to light. This type of ink works best on lighter-colored garments.

Tag Printing

Screen-printed tags are only a 1 color option. The maximum size for tag prints is 4″ x 4″.

Get a more custom, retail-quality finish with custom shirt tag printing. Tag printing is virtually unnoticeable to the touch thanks to our soft inks. No more itchy annoying tags!

We do remove the manufacturer’s tag, but please note that tags torn off sometimes leave small pieces of the tag in the seam. We are not liable to remove all pieces of the tag should some remain in the seam.

PMS Color Matching

In Flight uses a standardized color-matching system to ensure color accuracy is reproduced. We currently have PMS, Victory, and Athletic colors in stock.

What is PMS color matching?

PMS color matching in screen printing is to create a specific Pantone color. Pantone colors are standardized color codes used by designers, printers, and manufacturers around the globe. Please note that we have a tailored standardized colored chart. Colors outside of our standard chart will be subject to an upcharge.*

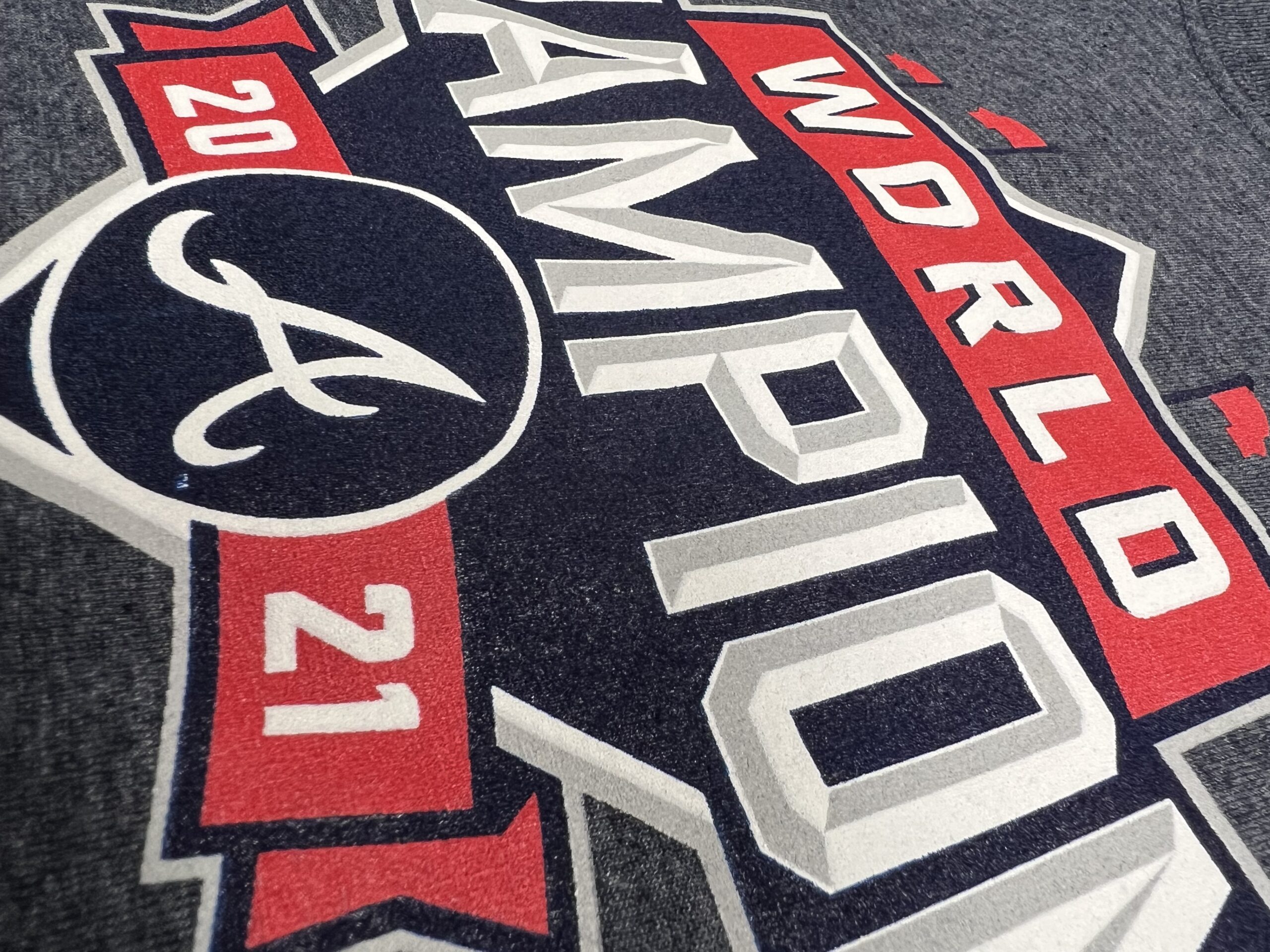

For example, We have the Atlanta Braves 150th-anniversary Northside Hospital print that shows many colors, five to be exact.

First, we will look at the red as we are required to match this red to the order, in which case it is PMS 200. Pantone colors are important to match because the red could change to another PMS color, and it wouldn’t be accurate with the Braves’ colors not identical.

This goes for many other company logos and brands out there because we know how important your design is to match what’s on the door.

![_DSC0188[1] screen printing](https://inflightprinting.net/wp-content/uploads/2023/01/IMG_0118-rotated-e1673445830744.jpg)

![_DSC0188[1] screen printing](https://inflightprinting.net/wp-content/uploads/2024/01/DSC01881.jpg)

![_DSC0206[1] screen printing](https://inflightprinting.net/wp-content/uploads/2024/01/DSC02061.jpg)

![_DSC0166[1] screen printing](https://inflightprinting.net/wp-content/uploads/2024/01/DSC01661.jpg)

![_DSC0197[1] screen printing](https://inflightprinting.net/wp-content/uploads/2022/12/IMG_0124-rotated.jpg)

![_DSC0197[1] screen printing](https://inflightprinting.net/wp-content/uploads/2024/01/DSC01971.jpg)

![_DSC0174[1] screen printing](https://inflightprinting.net/wp-content/uploads/2024/01/DSC01741.jpg)

![_DSC0168[1] screen printing](https://inflightprinting.net/wp-content/uploads/2024/01/DSC01681.jpg)

![_DSC0193[1] in flight screen printing logo](https://inflightprinting.net/wp-content/uploads/2024/01/DSC01931.jpg)

![_DSC0228[1] screen printing](https://inflightprinting.net/wp-content/uploads/2024/02/DSC02281.jpg)