Digital Transfer

In Flight remains committed to staying abreast of the latest trends and advancements, continuously expanding our services and resources to keep up with the ever-changing industry.

To fulfill customers’ digital transfer needs, we possess the necessary resources. Our facility has handled thousands of designs, encompassing intricate patterns and utilizing various screen printing techniques commonly employed in daily screen printing; we pride ourselves on offering premium methods that bring a fresh perspective to apparel printing.

So, we wanted to expand our knowledge from screen printing and take it digital. That is why we have introduced digital transfers to elevate our methods.

Digital Transfer:

The Process.

Digital transfer printing is a printing process that uses a digital printer to print out designs with transfer film. The film is then cut out and placed accurately on the substrate, followed by heat and pressure; the design is transferred onto the substrate. It is a versatile printing method that can be used on many materials; however, it’s mainly t-shirts and other promotional products. A digital transfer could be whole designs or names & numbers.

The digital transfer printing production process can be broken down into the following steps:

- Design: The first step is to create a design that will be printed. Like screen printing, design layouts can be created or edited using many software programs, such as Adobe Illustrator or Photoshop.

- Preparation: Once the design is finalized, the design layout will be prepared for pressing. Each transfer image must be cut out for the area you are heat-pressing. The heat-press unit must be up to the correct temperatures, typically 350-400 degrees Fahrenheit. Incorrect temperatures could lead to scorching or damage to the transfer film.

- Pressing: Once the film is placed in your desired location, heat and pressure are applied to transfer the image onto the garment. The surface area should be flat and smooth, as bumps or thread lines could change the transfer outcome.

- Curing: Once the item is pressed, remove the garment and let the film cool off before removing the transfer. Removing the transfer too early could lead to damages on the transfer.

Once the last garment is heat-pressed and cooled, it is packaged and shipped to your desired destination or ready for pickup!

In Flight Production

Where heat and pressure unite

Contact Us & Provide Your Design

Designs can be simple, or highly detailed with unlimited colors. Whatever design you request can be turned into a high-quality direct-to-film transfer ready to print on almost anything. Please make sure your designs are vector!

Transfers Digitized & Ready for Production

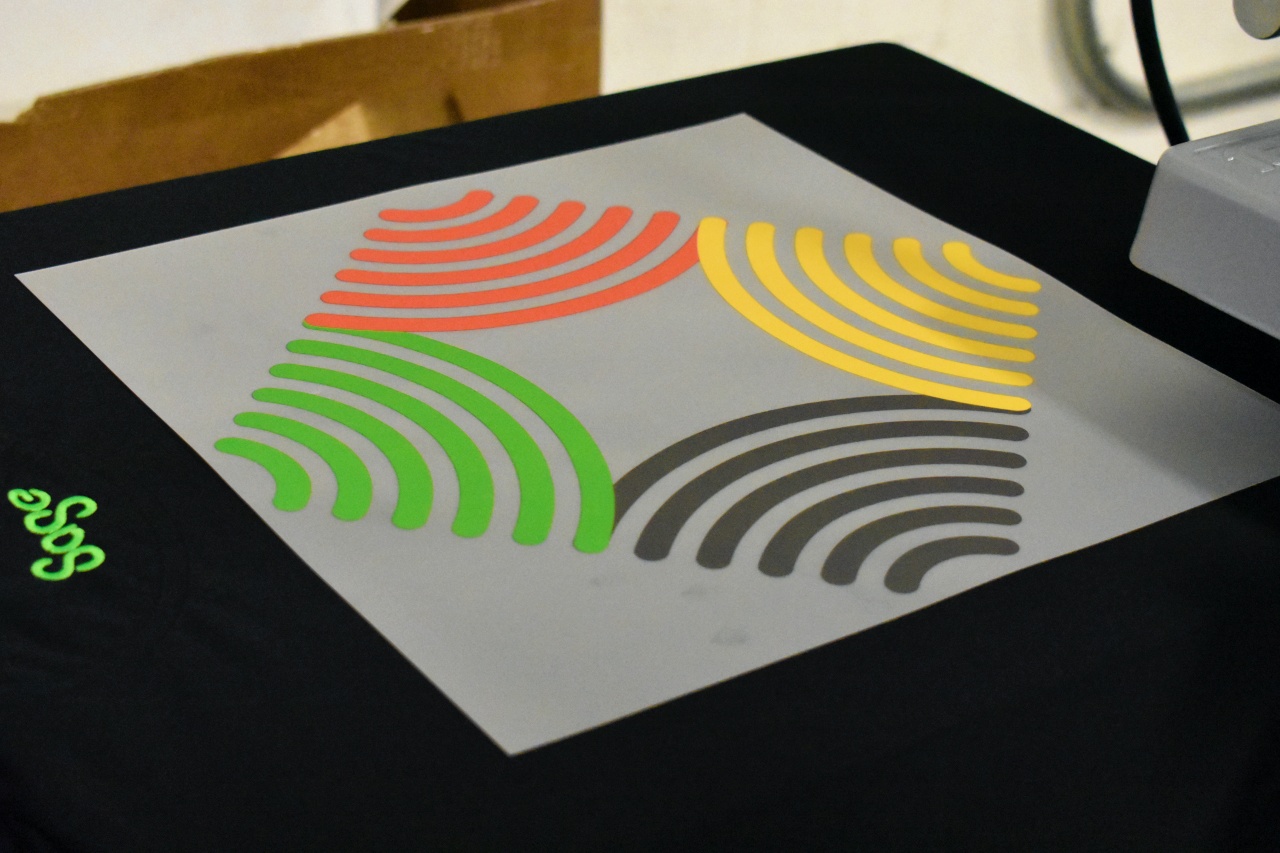

Once the designs are digitized and printed out on transfer film, we cut out each design and prepare them for production. This is the stage where we prep the order for transferring. Once the specs are aligned, we are ready to transfer!

Heatpress ready in 30 seconds

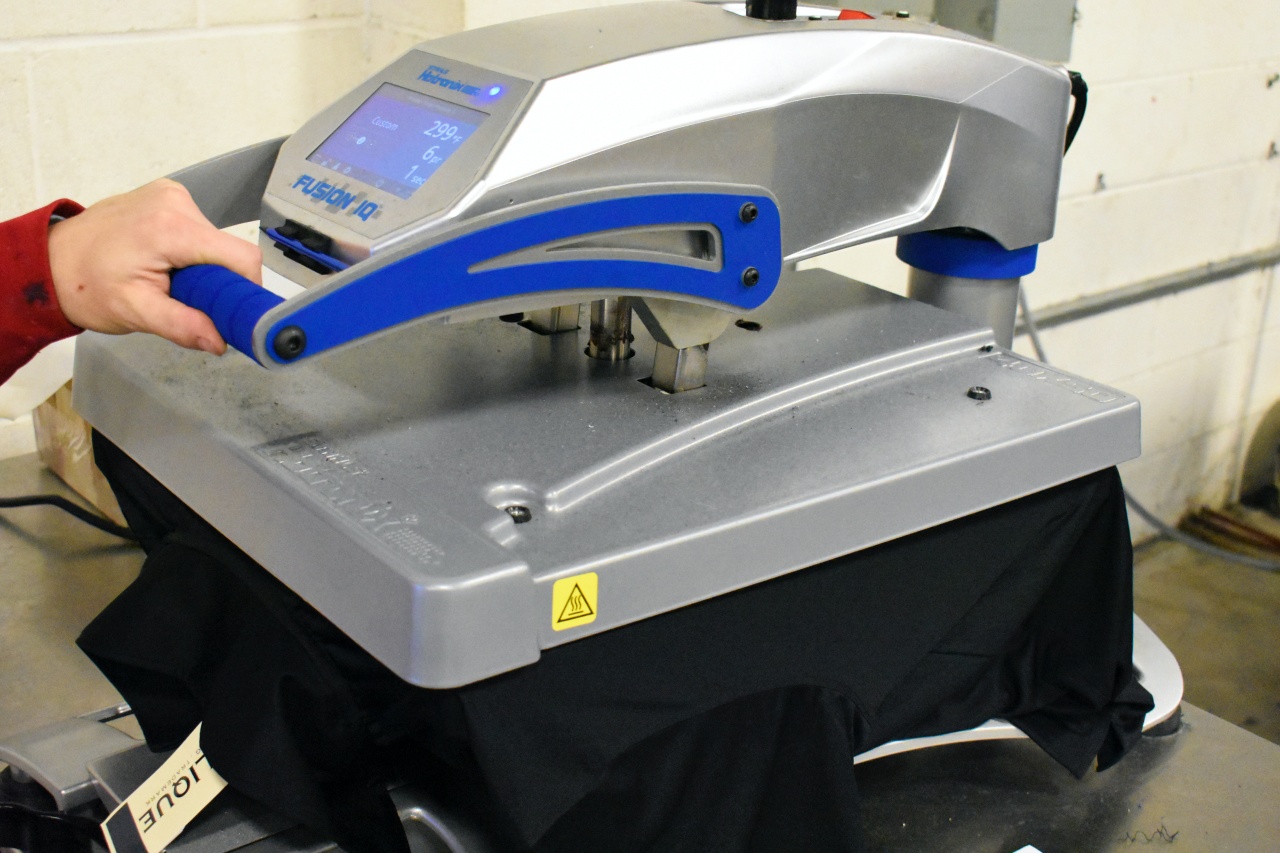

After staging is complete, now we set our heat press at 320°F with medium pressure for 12-15 seconds. After heat and pressure are applied, we allow up to 15 seconds to cool down before peeling away the transfer to reveal the finished product.

The process breakdown

Cut and Place Film

Once the transfer film is cut out, we can now place our design in its desired location of choice.

Heat Up and Press

Once the heat press reaches 320°F, you can now press your design for 12-15 seconds.

Cool and Peel

After pressing is complete, we let the film cool down so we can peel away the film leaving the perfect design in place.

Finished Product

Now that we have the film peeled away, the garment is ready to ship!